Introduction

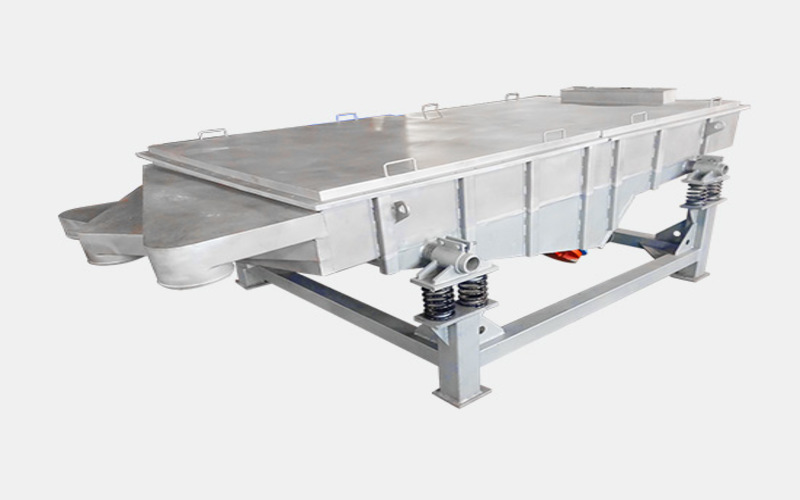

A linear vibrating screen is a category of plastic granulator series that helps you to process the material more effectively and efficiently. However, if you are a new buyer of this equipment, you must be wanting to know some basic information like selection as well as maintenance of your linear vibrating screen. Selection can be a difficult process especially when you are a noob and you don’t have enough knowledge about the machine. At the same time, even if you have bought the right machine then its maintenance can be a real headache for you. This blog will help you solve both the problems based on expert and professional manufacturers’ advice.

How To Select A Linear Vibrating Screen?

- When you are selecting a linear vibrating screen then you need to be clear about a few things first. Once you are completely clear with those requirements, you can choose or select the machine even without the help of an expert.

- First of all, keeping in mind the requirements of your final output, you should know the capacity that you want in your linear vibrating screen.

- Secondly, you need to be clear about the material that you will be separating through a linear vibrating screen.

- Then you should know the number of layers that you will be needing.

- The next thing is the sieve mesh size that you want for each layer.

- Lastly, particle distribution size is the most important thing to consider when choosing a linear vibrating screen.

- All the factors listed above can help you in a better selection for your linear vibrating screen.

How To Maintain A Linear Vibrating Screen?

When you are using your equipment on a regular basis, then it is quite obvious that it will require maintenance. Without proper maintenance, the machine doesn’t last long even if it gets damaged before its expected lifespan. To make your machine last for a longer time period, you should be very careful at using it and maintaining it. You can take advantage of years of trouble-free service through the linear vibrating screen by following simple steps :

- You need to inspect the machine on a regular basis to avoid any kind of failure in its components. If during the inspection, any kind of damage comes, you just need to replace or repair that damaged part immediately.

- You should make use of grease oil to lubricate the vibrator motors. However, make sure that you don’t over-grease the motor as it will cause overheating. Make sure that you use only the prescribed grease for the vibrator motor as any other low-quality grease may also result in damage to your machinery. Due to overheating, premature bearing failure can occur in your linear vibrating screen.

Conclusion

Most people ask for advice from manufacturers to select the right linear vibrating screen so that they start a business with the right product. However, they don’t get proper guidance. If you are one of those people, you just need to follow the steps given above. It will help you select the best product. Lastly, maintenance is an important process that you should never miss. You should follow the maintenance steps given above to maintain your machine.